Unboxing 3DEXPERIENCE Works

Starting a new project means setting yourself and your team up for success. With the tools and solutions in the 3DEXPERIENCE Works portfolio, the LID Boss team is able to set up tasks, manage software licenses, create a dashboard to share data and have a single source of truth, and much more.

3DEXPERIENCE Works Solutions Utilized:

LID BOSS Videos

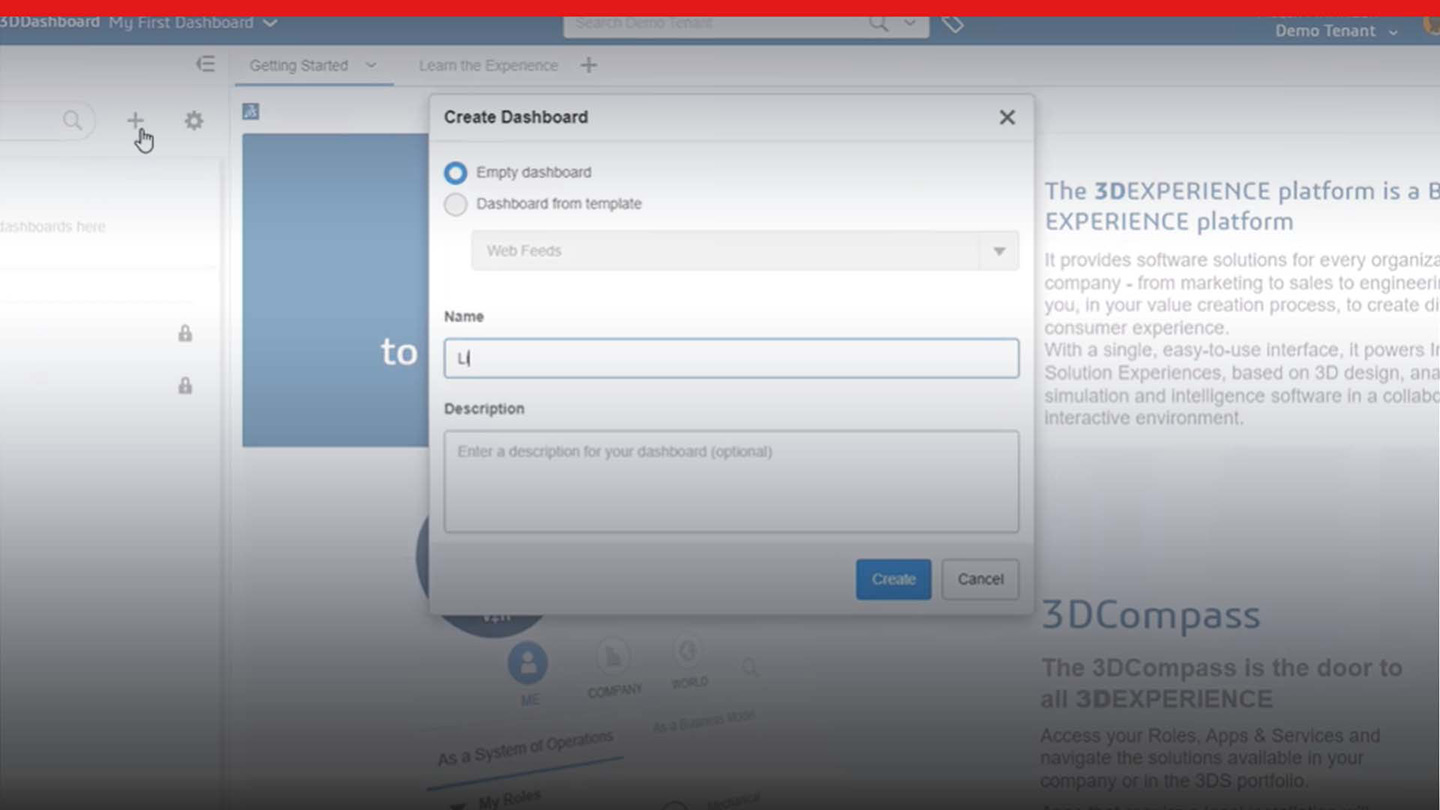

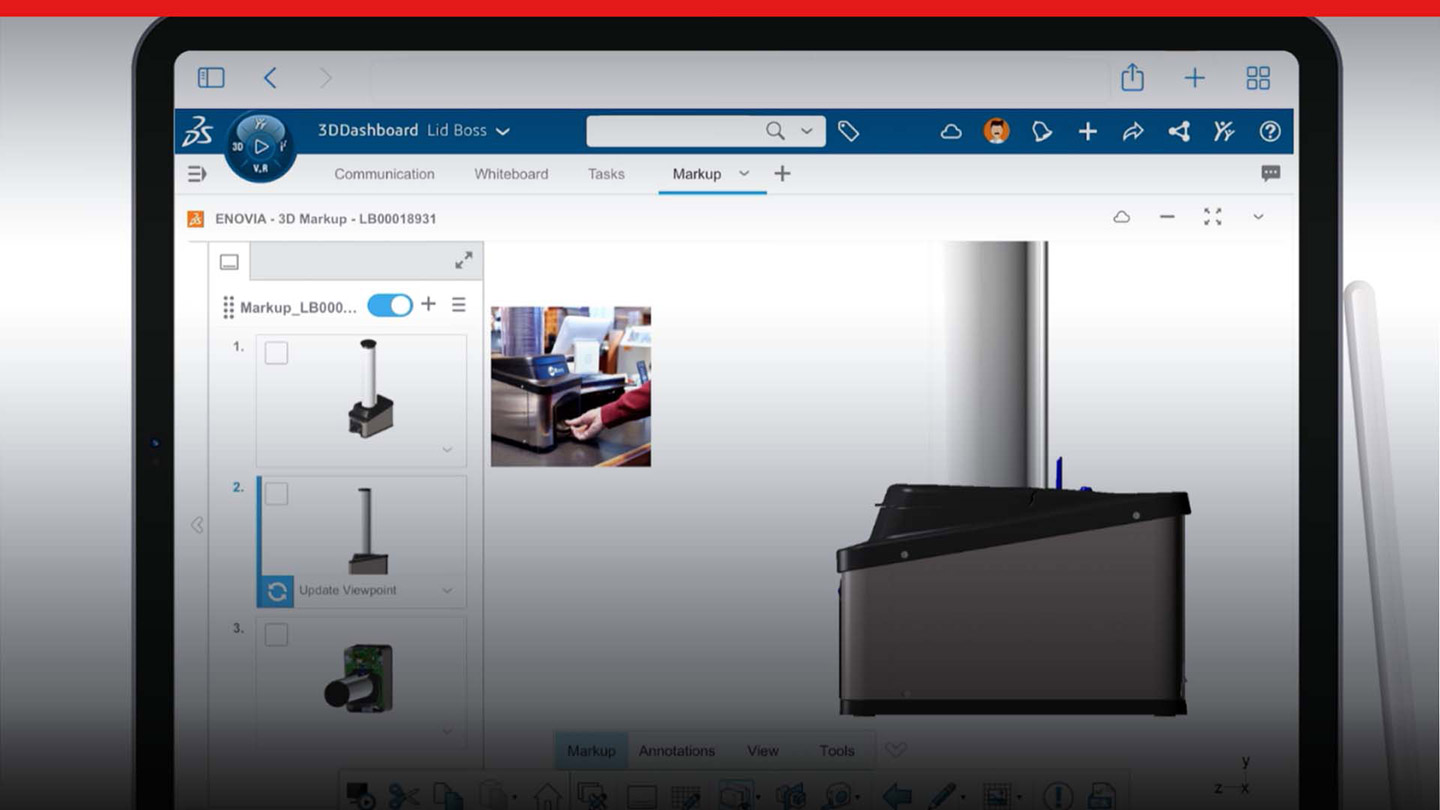

It’s time to start moving the LID Boss design to a production ready state in order to scale for global demand. With the challenges of a remote team and a fast paced timeline, Megan Manager centralizes her team’s goals on a unified, web accessible dashboard.

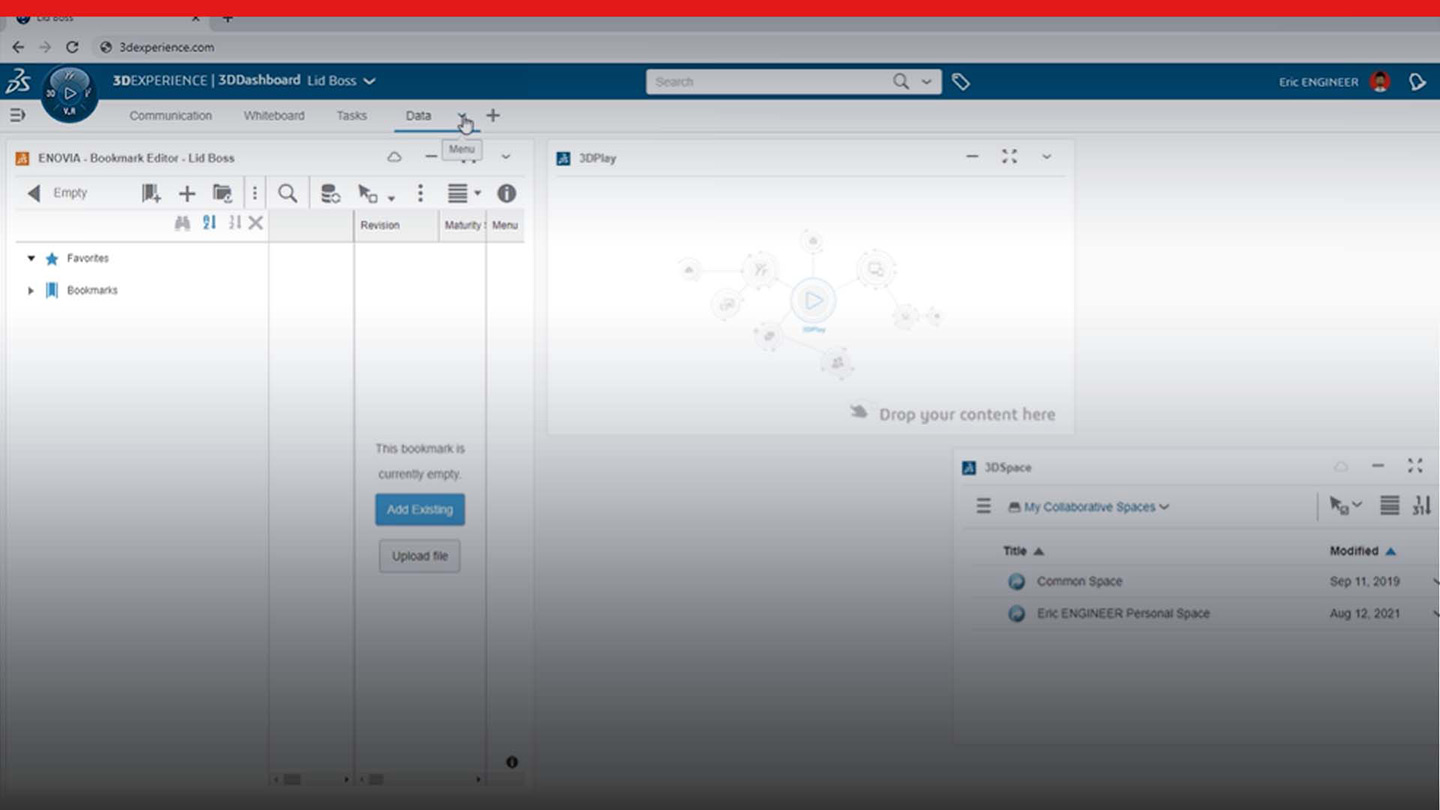

With the dataset officially handed off to the LID Boss team, Eric has been tasked with uploading and numbering the components to a secure and cloud accessible location. Eric also needs to make sure that Dan has all of the required licensing needs to get his job started.

Project Kickoff

It’s time to start moving the LID Boss design to a production ready state in order to scale for global demand. With the challenges of a remote team and a fast paced timeline, Megan Manager centralizes her team’s goals on a unified, web accessible dashboard.

Mechanical Design

What does it take to prepare a new product for manufacturing? For the far-flung LID Boss team, editing their design requires robust, cloud-connected and browser-based tools. The varied solutions in the 3DEXPERIENCE Works portfolio helps them optimize their design and get it ready for the next steps.

3DEXPERIENCE Works Solutions Utilized:

LID BOSS Videos

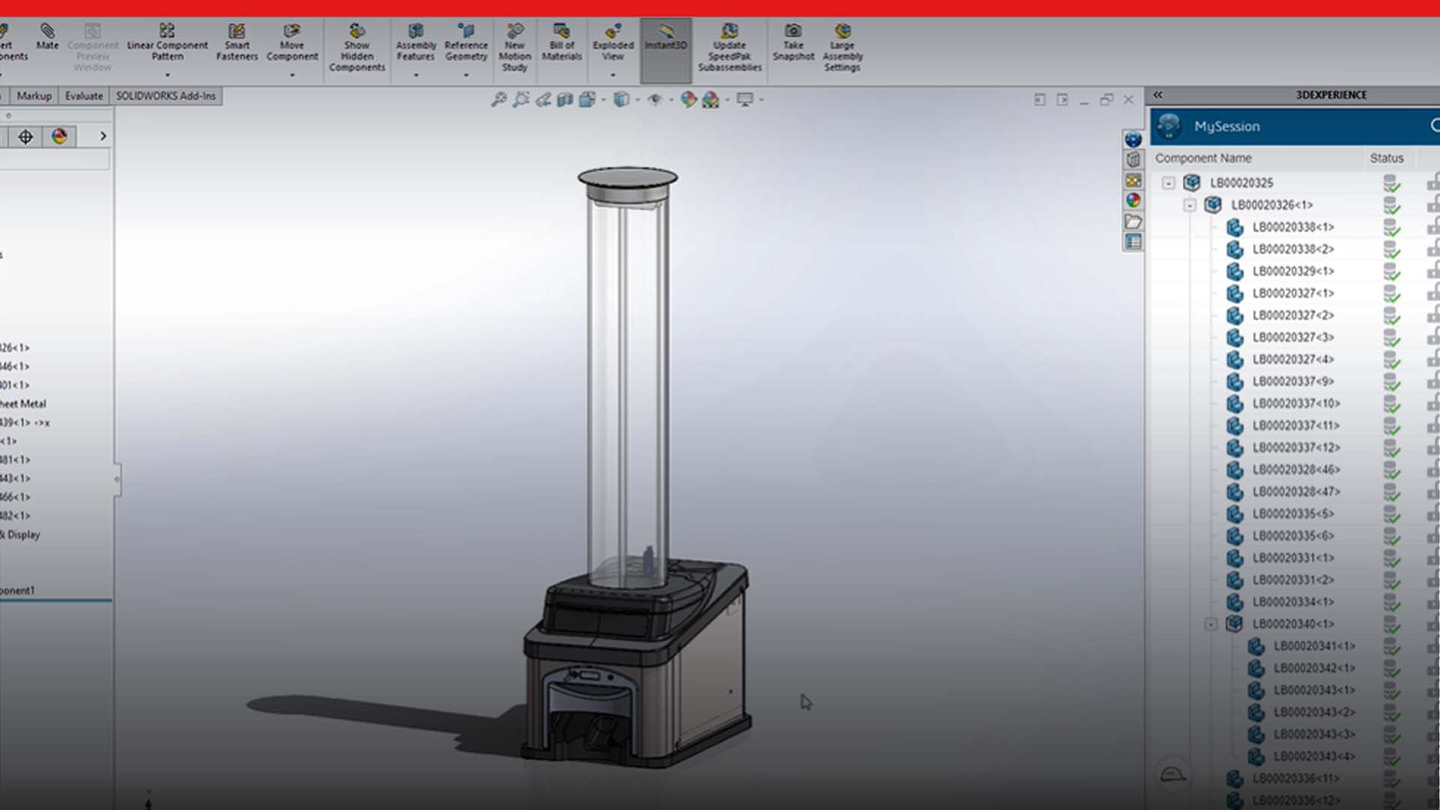

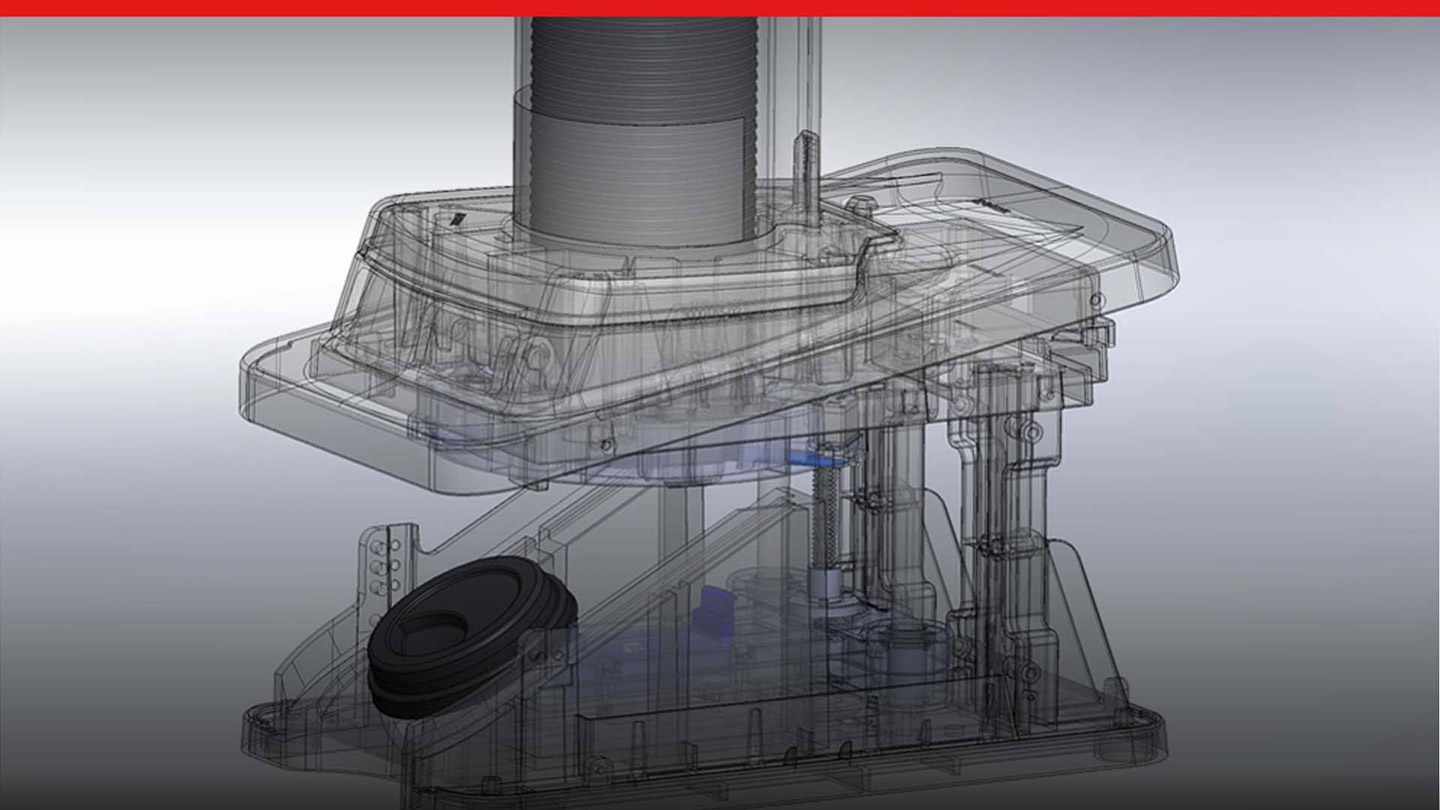

The original assembly was designed for rapid prototyping. Now it needs to be modified to accommodate large volume manufacturing methods like plastic injection. See how Eric uses 3DEXPERIENCE SOLIDWORKS to investigate complex components and modify the geometry.

The LID Boss’ plastic base is almost ready for mold tooling, but how can Eric be sure that the part is rigid enough to support the dynamic action of the shuttle? He simulates the mechanism using 3DEXPERIENCE SOLIDWORKS Premium, and optimizes the design to ensure proper performance.

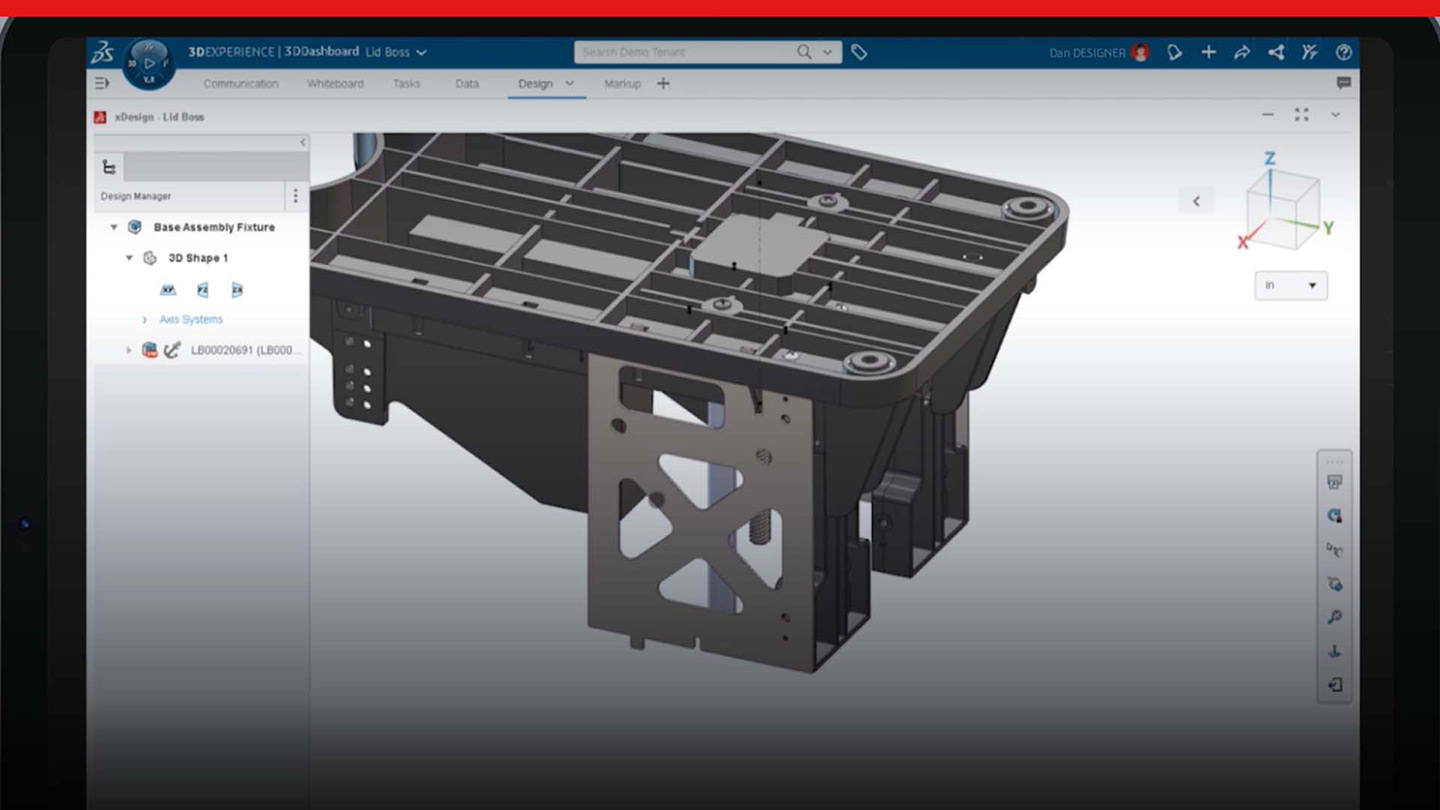

Dan is out of the office without access to his workstation or the project files. Watch Dan progress the design, while on-the-go, as he handles a task to build an assembly fixture. Dan uses the power and mobility of 3DEXPERIENCE Works to get ahead using down-time that would traditionally be wasted!

Base Unit Design

The original assembly was designed for rapid prototyping. Now it needs to be modified to accommodate large volume manufacturing methods like plastic injection. See how Eric uses 3DEXPERIENCE SOLIDWORKS to investigate complex components and modify the geometry.

Advanced Simulation

How do you get your product to the consumer? With proper packaging, of course. Sometimes, however, packaging can be overdesigned and made from the wrong materials, leading to unwanted extra costs. Fortunately the 3DEXPERIENCE Works portfolio has powerful simulation and analysis tools to help redesign the LID Boss’ packaging.

3DEXPERIENCE Works Solutions Utilized:

Virtual Package Drop Test

In order to ship the LID Boss around the world, Eric needs to design and validate the packaging. But due to industry regulations, he needs to make modifications. See how Adam Analyst and Eric leverage the power of 3DEXPERIENCE Works and the cloud to simulate real-world scenarios.

Going to Market

Bill of Materials, documentation for manufacturing, product renderings for sales and marketing…there is so much that goes into getting a product to market than just designing it. The LID Boss team is able to create gorgeous, realistic imagery, identify at-risk parts, and much more using the tools in the 3DEXPERIENCE Works portfolio.

3DEXPERIENCE Works Solution Utilized:

LID BOSS Videos

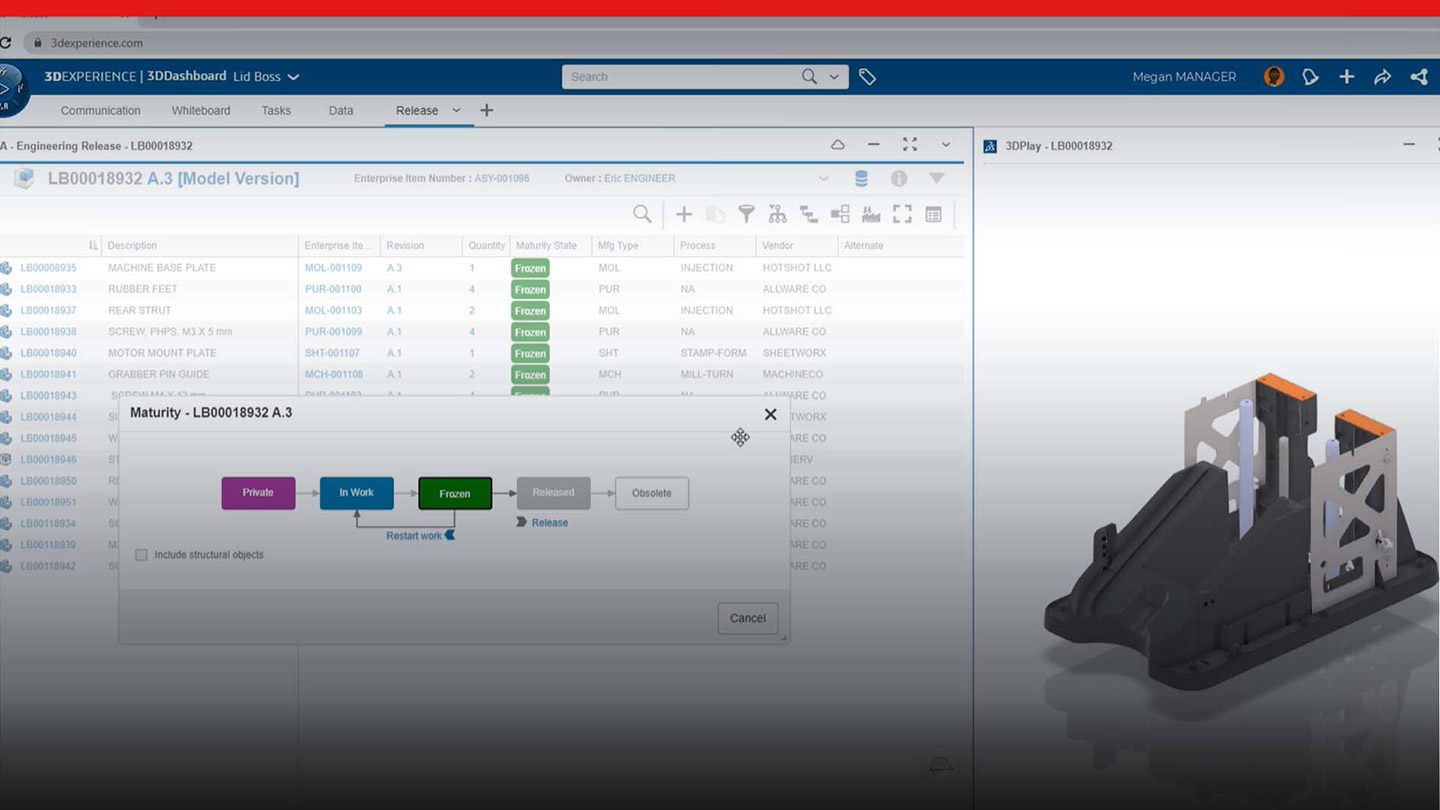

To manage the complexities associated with the design release process, Megan utilizes Product Release Engineer. See how having a single source of truth for product definition, powerful data visualization, and easy to use filtering and export allow Megan to fast-track getting the LID Boss released.

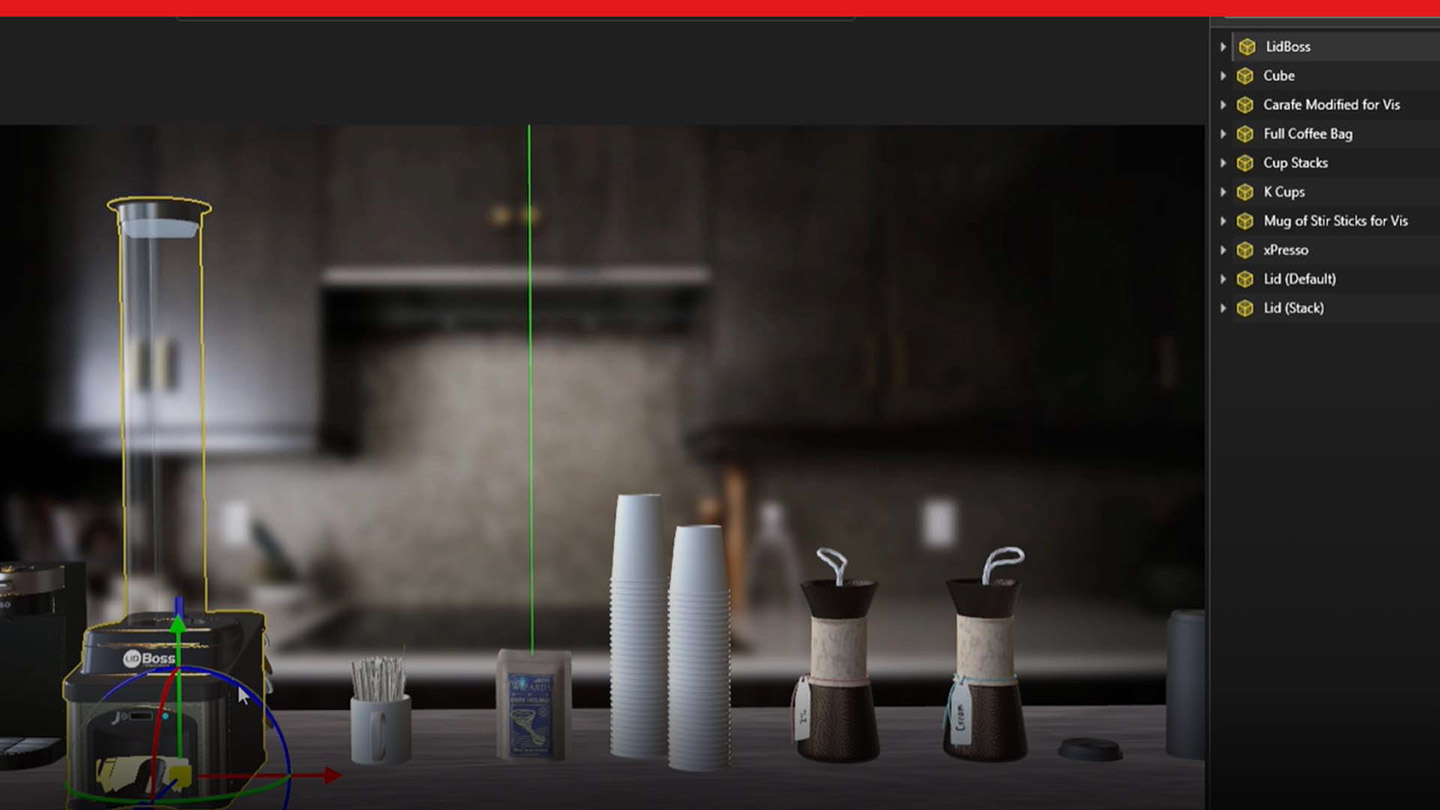

Dan knows that seeing is believing. He turns to SOLIDWORKS Visualize Connected to produce striking images of the LID Boss. Watch as Dan quickly builds a scene, creates several variations, generates high-quality content, and shares with the team using the 3DEXPERIENCE Platform.

Product Release

To manage the complexities associated with the design release process, Megan utilizes Product Release Engineer. See how having a single source of truth for product definition, powerful data visualization, and easy to use filtering and export allow Megan to fast-track getting the LID Boss released.

Closing the Loop

The tasks are complete, the product is being manufactured, and customers are sharing their feedback. How can the LID Boss team track issues and respond to necessary changes? No matter where they’re working from and what stakeholder they need to connect with, the 3DEXPERIENCE Works portfolio has what they need to make the LID Boss even better.

3DEXPERIENCE Works Solution Utilized:

LID BOSS Videos

Megan reviews the LID Boss team’s assigned tasks and makes sure nothing was missed. The tasks deliverables give her a chance to review part revisions, simulation reports, 3D drop test results, and even assemble a presentation made from Dan's marketing assets on the fly!

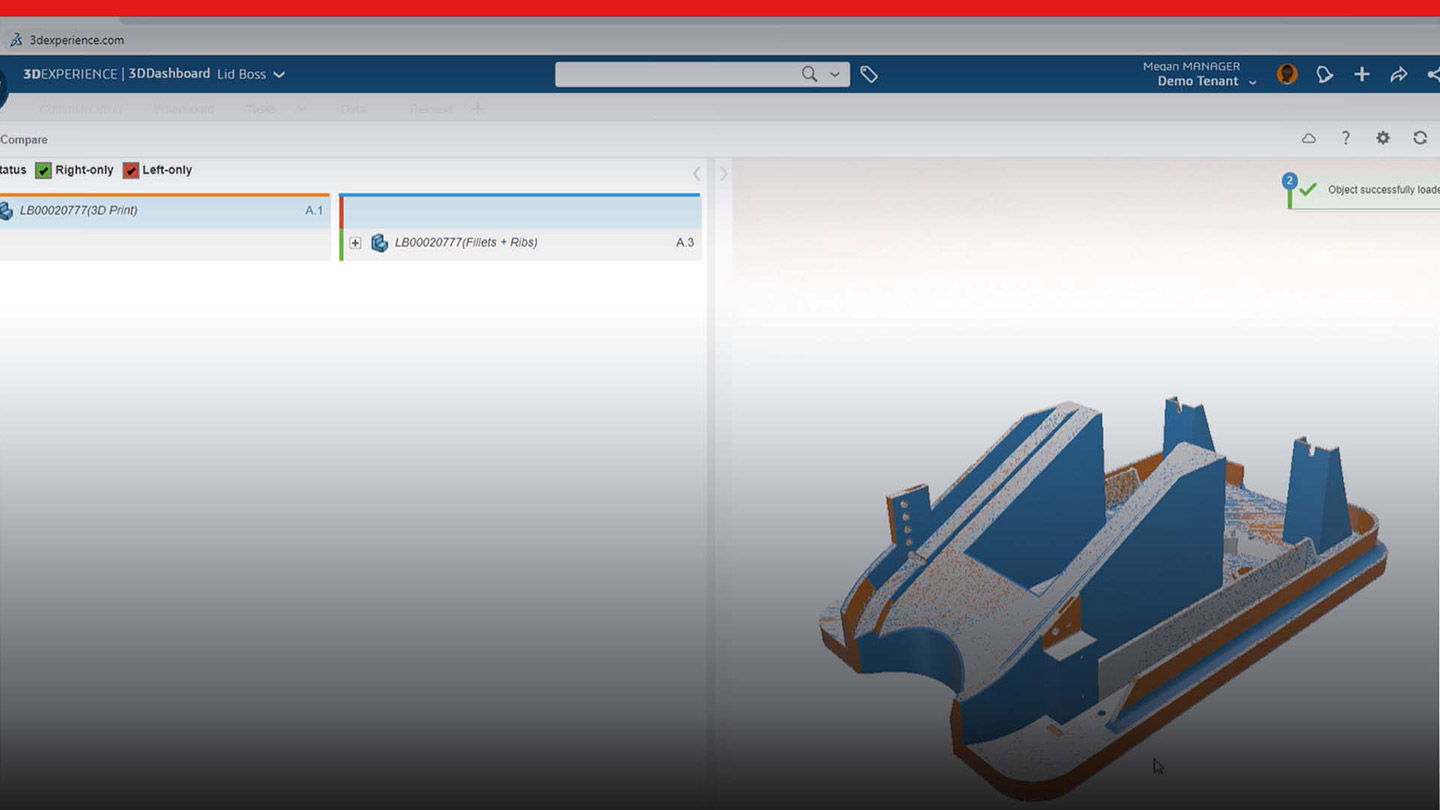

Addressing customer feedback and efficiently implementing design changes is critical to the continued success of LID Boss. See how the team used the 3DEXPERIENCE platform to seamlessly implement customer feedback in a fully connected, end to end change process.

Project Update

Megan reviews the LID Boss team’s assigned tasks and makes sure nothing was missed. The tasks deliverables give her a chance to review part revisions, simulation reports, 3D drop test results, and even assemble a presentation made from Dan's marketing assets on the fly!

Put a Lid on It

Seize opportunities and overcome any go-to-market challenges with the solutions in the 3DEXPERIENCE Works portfolio.

Based on a survey of 187 manufacturers, this research study examines industrial design, where time is wasted, and best practices to avoid non-value-added work.

Based on a survey of 228 manufacturers, this research study examines machine design practices, where engineers waste time, and best practices to avoid non-value-added work.